How much moisture does your concrete transmit? This is an important question that needs to be addressed before you decide to apply epoxy or paint to your garage floor or basement. If you are unsure, then you need to perform a simple moisture vapor transmission (MVT) test at the surface of your concrete before a coating is applied. Your coating, as well as your hard work, may be destined to fail if you don’t.

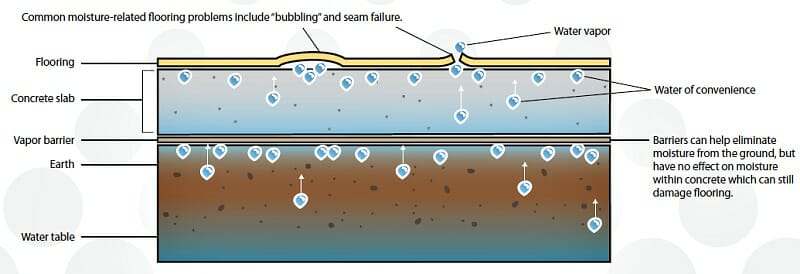

As hard and dense as concrete seems to be, it is actually very porous. If moisture is present beneath the slab, it will permeate to the surface of the concrete. Because coatings such as epoxy are impermeable and do not breathe, water vapor and moisture can’t pass through the coating.

Moisture that passes up through the concrete carries calcium and sodium chloride salts to the surface. If they are blocked by the coating, the buildup of moisture and salts will cause the deterioration of the uppermost layer of concrete that the coating is attached to. This is what causes the coating to peel or delaminate. Though paint will breathe, anything greater than light moisture vapor will cause paint to peel as well.

For slabs that are below grade, hydrostatic pressure can develop if moisture transmission is blocked. This pressure can be strong enough to pop chunks of concrete along with it if a high-performance epoxy or coating has been applied.

Your concrete may already show signs of moisture issues and you don’t even realize it. If there are any areas of your garage floor or basement that always seem to have a white powdery residue that comes back after cleaning, then you most likely have efflorescence. Efflorescence is created when moisture travels through the concrete, condenses and evaporates, and then leaves a residue of calcium hydroxide (white powder).

If you have an area of your concrete or garage floor that always seems damp, then this is a sign of moisture problems as well. This can sometimes be caused by leaky pipes or drains under the slab or poor drainage from the perimeter of the slab.

So, where does this moisture come from? In simplified terms, the porosity of concrete causes it to act like a sponge. If the ground that your slab was poured on is consistently damp due to climate or other factors such as water drainage or irrigation issues, then your slab will naturally draw in moisture from the ground.

If the surrounding air at the surface of your slab is drier than what is underneath, then the moisture that your slab has collected will be transmitted to the surface of your floor as it tries to equalize. This reaction can be enhanced if your slab was poured below grade. In other words, lower than the surrounding earth.

Don’t confuse a sweating garage floor with moisture from below. Condensation (AKA sweating) is an environmental condition that allows water to condense on the surface. This has no effect on a coating since it develops on the surface and not from below the slab.

This post may contain affiliate links. If you use these links to make a purchase, we may earn a small commission. As an Amazon Associate, All Garage Floors earns from qualifying purchases. You can read our full disclaimer here.

How to moisture test concrete

The easiest way to determine if you have moisture that transmits through your concrete is to test for it. A simple way is to perform the ASTM-D-4263 Plastic Sheet Test.

You can do this simply by cutting a 16”x16” piece of plastic sheeting and taping down the perimeter with duct tape to the surface of your garage floor.

After letting it sit for 24 hours or more, peel it up and look for any condensation on the underside of the plastic or look for a dark spot on the surface of the concrete. Water on the underside of the plastic or a dark spot on the concrete is created from moisture. If none exists, then you should be fine. If you do have moisture then you will want to do a calcium chloride test to see how much moisture you have.

Great information on how to perform a calcium chloride test as well as check your concrete’s PH level.

A calcium chloride test is used to determine exactly how much moisture you have emitting from your concrete. This is done by placing a pre-weighed petri dish of calcium chloride on the slab and then covering it with a sealed plastic container. After a predetermined amount of time, you remove the petri dish and re-weigh it. Once you determine the weight difference, you generally can enter the results on the manufacturer’s website or look it up in an included pamphlet.

Calcium chloride moisture test kits can easily be purchased here at Amazon. You will also need to purchase an inexpensive digital gram scale if you do not already have one. You can find them here at Amazon as well.

As long as your results are less than 3 lbs of moisture flow per 1000 square feet per 24 hours, then you will be safe to apply most coatings.

If your results are higher than that, then you will need to consider applying a moisture blocking sealer or moisture blocking epoxy primer before coating your garage floor. Of course, there is always the alternative of deciding on a different garage flooring option.

One important factor you need to be aware of is that often a moisture test is only indicative of the current conditions. In other words, you may not have any moisture at all if you are testing during a period when there has been little rain in your area of the country. It is best to test during the wetter part of the year when possible moisture issues would be most prevalent.

Of course, if your slab is above grade, doesn’t show any signs of moisture, and you live in a fairly arid part of the country, then doing a moisture test is most likely not necessary.

Just remember, of all the things that need to be considered before you decide on an epoxy coating or paint for your garage, determining if you have a moisture issue is the first step. It’s easy and fairly quick to do and can save you from the disappointment and anguish of a failed floor coating.

I had a 600 foot garage with a cement floor grinded, epoxied, and then a clear coat over the top of the flake. I had it professionally done by a reputable company. Left it for a day to dry. Went back in there this afternoon (48 hours after clear coat was applied) and the whole garage floor is wet. Never had a water prob in their before. Garage doors were left open for hours. I live in downstate NY. Any ideas why this is happening or what I could do to fix something like that. It’s like the floor is sweating but epoxy is suppossed to be a sealer, no?

Hello Craig. Yes, epoxy coatings completely seal the concrete. It’s wet on top because the floor is sweating and the epoxy is not allowing the water to penetrate into the concrete. Sweating occurs when relatively warm moist air comes in contact with a relatively cooler surface (your garage floor slab) with a temperature that is below the dew point. When you left your garage floor open for 48 hours, you allowed the warm moist air to come in and settle on your concrete. You need to remember that concrete can hold its temperature for days, not hours. Living where you do, the concrete most likely was very cool when you left the garage door open. This article here explains more about what concrete sweating is.

Hi there,

I was asked to provide a quote for a customer and I noticed some Efflorescence on the concrete slab. Not a lot, but a little.

I typically diamond grind, apply a 100% solids epoxy primer, then epoxy, then chips, then a top coat.

Should I be considered for failure based on the efflorescence?

A little efflorescence may not be a problem, Randy. Typical epoxy primers can withstand a moisture rate of 3-4 lbs per 1000 square feet per 24 hours. Your supplier should have that info. However, you won’t really know until you moisture test first to determine if there is moisture to be concerned with and if so, how much there is.

Hi there,

Do you guys have any recommendation on companies that perform this type of service? I’m located in Weston, Florida.

Hi Ernesto. No, we are not familiar with such companies in Florida. However, if you are looking to hire a company to do a floor coating installation, most will be able to perform the tests for you.

Thanks a lot!

Hey Ernesto i own an epoxy company in the weston area. We also specialize in moisture testing. Feel free to reach out and schedule a quote.

Daniel

The Epoxy Pros

954-994-9220

We have water come up through our basement floor. Only in spring when the ground is thawing. Several different areas. Not near walls at all. We have a sum pump in this area. Will this process prevent this?

Hi Ella. What process are you referring to? This article is about testing for moisture. If you are inquiring about the moisture vapor blocking epoxy primer, then no, that will not work. These primers are for blocking moisture vapor, not that much physical water that is coming up through the concrete.

Hi all,

I have the same problem where water will come from the flooring when there is numerous days of rain. I had a company come by and said tha the epxy should take care of that. Is that true

Hi Denis. No, it’s not true. Unfortunately, there are companies out there that will say just about anything to get business. If you check their warranty, I’m willing to bet that it will not cover issues of the coating peeling up due to moisture in the slab. That’s exactly what will happen after a few years. There are special moisture vapor blocking epoxy primers that can be applied to block such moisture. However, they are expensive and require aggressive grinding for the epoxy to penetrate and take proper hold. Unless they are quoting for such a system, they are not being truthful.

Is there a section of your slab that is up against a hill or below grade? If not, I would investigate why you have the water issue. It could be something as simple as a downspout dumping water up against the slab or water not draining away from the foundation and instead collecting up against it.

Hi All.

The builder just delivered my new build home. Concrete is probably 30 days old. No sealant. Do I need to wait a couple of months to curate the concrete?

Many thanks.

Moris

Hello Moris. I’m not quite sure what you are asking. You need to wait a minimum of 30 days for new concrete to cure before you apply a sealer, if that is your question.

Hi, it was to apply the epoxy.

Yes, then 30 days is how long you need to wait. Even though the concrete is new, you will still need to properly profile the surface by either etching or grinding the concrete. This article here explains more.

I have a small room on the 3rd floor the walls built by concrete blocks and the ceiling poured slab of concrete. In winter the ceiling and concrete will have large wite flacky spots developed from moisture. Can you recommend a solution please

Hi Mike. We would recommend a product that is used to seal basement walls. RadonSeal is one such example.

Can I use Rustoleum moisture stop before using an epoxy kit to avoid moisture related problems on my garage?

Hi Avi. You can use it, but it does not guarantee it will prevent any moisture issues you may have with the coating.

Thanks for your response. What other products can be used to prevent moisture issues before coating the floor or should I just stick to regular solvent based sealers?

Have you confirmed you have a moisture issue via testing?

Can a epoxy flooring be applied to my garage is a moisture reading is 6?

Hi Kurt. If your moisture test has determined that you have 6 lbs moisture flow per 1000 square feet per 24 hours, then you far exceed what is acceptable for a typical floor coating. You will be required to perform and aggressive concrete grind and then apply a moisture vapor blocking epoxy primer first.

I have a below-ground basement that has french drains along the exterior walls. After recently removing some damp basement carpet and foam padding (to expose the concrete floor), I’ve noticed water puddling (1/4” or less) in sections of the concrete slab after heavy rains. Assuming that it’s hydrostatic pressure at work, as the water dissipates within a day or two. I’m debating new waterproof flooring options (interlocking rubber tiles, LVF, etc), but before proceeding I’m first trying to determine whether I should do anything to the concrete floor. My inclination is to do nothing to the concrete, instead laying a 3/8” interlocking plastic drainage tile directly over the concrete and then the waterproof flooring over the drainage tile. In the event of heavy rains and possible puddling, I can simply lift out the interlocking tiles in the area of the puddling, let them dry, and put the flooring back in place once the concrete is dry.

Thoughts?

Thanks!

Hello Robert. What do mean exactly by waterproof flooring? The interlocking drainage tiles as a subfloor would work. However, if you apply something over it that will not allow the moisture vapors to escape through, you may develop mold and mildew on the underside of that flooring.

Thanks. By waterproof flooring, I mean an interlocking rubber tile or a modular luxury vinyl floor (in either case, they would sit on top of the drainage tiles). In the event that I got some water after heavy rains, I could lift out the interlocking floor tiles to let them dry and give the water an opportunity to evaporate.

Yes, that would work Robert.

I have a double garage which has a concrete floor which shows signs not only of efflorenscence but generally, moisture. The water table is not far below, the climate here is very humid, and in my neighbourhood all houses are built in a clay type of soil. My worry is that if I cover my garage floor (by a professional) with epoxy or something similar, the concrete will not have a chance to breathe. Ever. On wet days, the concrete show darder areas all over. On dry days, I open the door to dry-up the garage. But of course, the mess and hugliness of the floor is why I would like to put epoxy. Could I create harm here?

Hi Nina. Coatings do not do well if moisture is coming to the surface from the ground underneath. There are special epoxy primers that can be used to block that moisture, but they are expensive and require aggressive grinding of the concrete for prep. The coating would then be applied to that. Are you positive that this is where the moisture is coming from? In many areas of the country where high humidity is present, condensation can form on the concrete and make it appear as though it’s coming from underneath. It’s commonly referred to as a “sweating slab”. We have an article about it here. If the water is from below, then we would recommend installing interlocking garage floor tiles instead. They allow air to pass under the tiles. This will help to dry the concrete when it gets wet and will not trap moisture under the flooring.

Hello,

I had a company install epoxy flooring last year just before winter. This summer the garage smelled strongly of chemicals and developed small black spots on the top grouped together but spread randomly in the garage. They did install a vapor barrier but I fear it may have failed. We do not use the garage in the summer but do in the winter.

The company says the garage just needs to air out for the smell, which I did for about a week during the summer and it did not help. They also told me the black spots could be oil build up which is impossible as we use the area a “man cave” and seldom have anything with oil in the garage.

Any help would be appreciated also I can provide pictures if that helps.

Hello Caleb. I have a few questions. Was it a moisture vapor epoxy primer that was applied? If so, why? Is the slab below grade? Did they grind before application? Was a moisture test conducted to determine what type of moisture blocker to use? Besides the moisture vapor barrier, what other coating products were used exactly? Epoxy is a vague term that people tend to use for garage floor coatings. Was a polyurea or polyaspartic coating used? Do you know for a fact there is no oil in the concrete because you are the original owner of the home?

I emailed you a response but I just talked with the vendor and they stated they may sand off the top layer and put down a new top coat. Do you think this is worth a try as I have to move so much stuff and if the end result is to grind off the entire floor why move the stuff again when this fails. The vendor did say they mixed the top coat with xylenes to slow the cure process to make it easy to work with as it was installed in October in Minnesota so it was cold. The issue I now have is it is cold again and the smell is going away but reading from someone with a similar experience it will come back in the summer when the ground heats up again. This was installed 1 year ago. Thanks for your continued responses.

Hi Caleb. Yes, the black spots could very well be oil then. It could also be mineral deposits from the concrete left behind when water is forced up through the coating and evaporates. Does the black residue feel slippery/slimy or is it gritty? Does it have a smell to it?

Xylene will help to increase the pot life of high solids coatings, but it also increases the coverage rate. This is a typical practice that some installers use to reduce the amount of material otherwise required. The customer pays for a higher solids coating but isn’t getting it because it’s reduced by the Xylene. Did they use it for the color coat underneath the top coat? In colder weather, solvents such as Xylene need more time to evaporate out. If that time is not provided, then it can off gas for months and sometimes years. I would request more information from the installer on what was done exactly for the entire system. You might be OK with replacing the top coat, but if they did the same for the coat underneath, then we would recommend removing it all, unfortunately.

Hi Shea! We haven’t spoke for while. Still having problems with the Epoxy floor 1+ year after install. Horrible smell that won’t go away and yellow spots all over the floor seeping up from the concrete, and getting worse. I have a few concrete guys over, and they all say there is moisture from the slab (under the slab) trying to push it’s way up, thus the yellow spots. And my original Epoxy contractor says he did apply a vapor barrier and has no advice expect to chop up the floor and pour a new concrete slab. FYI…my garage has always been humid.

Anything else to try besides chopping up, adding a moisture barrier, and repouring the concrete (costly!) I would then leave the concrete as is, or maybe get some removable tiles for where the car parks. Also, should my Epoxy contractor have performed a moisture test? THANKS!!!! Steve

Hi Steve. We are sorry to hear about your moisture issues. If a floor coating contractor or company believes they need to apply a moisture vapor blocking epoxy primer, then it’s imperative to first determine the amount of moisture content of the slab. All moisture vapor blocking epoxy primers have various limitations for blocking moisture. Testing will determine IF a moisture blocking primer can be used and which type is based on the moisture content. Blindly applying a moisture blocking primer without testing first is just guessing.

Yes, ripping out the old slab, installing a proper moisture barrier, and then placing a new slab over that is costly. Our recommendation to save money would be to remove all of the coating via grinding and then treat the bare concrete with a densifier. We would recommend two applications. Densifiers work by reacting with minerals in the concrete to produce CHS (calcium silicate hydrate). The CHS hardens the surface and fills many of the open pores and capillaries at the subsurface. This will help to reduce the moisture intrusion, but it will not stop it when it’s severe as in your case. After that, we would recommend choosing an interlocking floor tile system. These systems breathe and allow air circulation under the tile and will not be affected by the moisture.

So is moisture in a slab only a problem for curing epoxy, or also for fully cured epoxy? In other words, if my slab passes all the moisture tests now, but has some moisture a few months from now, will the cured epoxy I put down now still be in jeopardy when the moisture problem arises months from now?

Hi Greg. Moisture that comes up from below the slab on a semi-consistent basis is not good. If you have a known problem with moisture coming from below the slab (not a sweating slab) then you run the risk of the coating delaminating. Water that travels up through the concrete carries calcium salts with it. When these build up under the coating, it causes deterioration of the uppermost layer of concrete that the coating is attached to.

Thanks. Seems like a moisture test doesn’t eliminate the risk over time then. You’d have to do a test during a particularly wet seasonal stretch to be sure. I just did a moisture test and it was fine, and I’ve never visibly seen moisture as a problem, but this is the first and only time I have ever tested for it.

That’s correct, Greg. There are indicators that will give you a better idea if moisture may be an issue or not. Occasional efflorescence in areas, below grade slab, damp spots at certain times of the year, etc. If none of these apply, then chances are moisture is not an issue.

Hi Shea. This is so helpful. I’m hoping you can advise me as well.

I have a basement that sweats. I live with a brook uphill that runs under my house to a lake 30 feet away from my house. I don’t get water in my basement, but it sweats. The walls sweat, too.

The paint is chipping off the concrete and the salts are coming up from the concrete.

I don’t believe epoxy is the answer for me. I believe the floor should “breathe”. Can you recommend a course of action for me?

Hi Michelle. I think we need to get the terminology correct to make sure we speaking of the same issue. Sweating concrete refers to condensation. When moist and relatively warmer air comes in contact with cool concrete, the air condenses and releases moisture on the surface. This article here discusses sweating concrete. It sounds to me like you are dealing with a separate issue which is moisture from the surrounding ground traveling through the concrete. Concrete actually acts like a stone sponge. If the moisture cannot evaporate quickly enough as it reaches the surface, the concrete will turn dark or get wet. Can you verify which condition you have? Also, what is your goal for the room? Do you want to install a flooring of some type or are you just looking to stop the moisture issue?

Hi Shea,

You are correct – the floor gets moist from underneath. I’m sure that’s correct because I have rubber matts covering the floor and they are wet underneath. The wall is only wet near the bottom, as if it’s also coming up from the ground.

My goal is to coat or cover the floor with something. It’s not a perfectly finished basement, but I don’t want the paint chips and cement crumbles any longer. And the rubber matts seem to be making it worse, they get moldy and I have to replace all the time. Plus the corners of the matts curl up and trip me.

So I would like some kind of coating. Vinyl flooring won’t work because the floors are too uneven. Tile would be too much for this humble basement.

I’m told that epoxy will fail over time because the cement will continue to act like a “floured baking dish” as the moisture continues to break it down.

Then I was thinking cement would work but I was told that I would have to jackhammer 4″ off the top and lay a new coat of cement that thick, otherwise a thin layer of cement will simply crack on top.

Thank you!

Hi Michelle. OK, we were going to recommend interlocking floor tiles, but it sounds like they may be more than what you want to spend. These TruLock tiles here are sold in ten packs and are about the least expensive and good quality if you want to take a look. The nice thing about interlocking tiles is that they allow airflow underneath and you don’t have to worry about mold or mildew. If that option is too much, then you can try DryLok Floor and Masonry Waterproofer. It’s breathable and may work to stop your dust and moisture problem. You are correct about epoxy and similar coatings. They will not allow moisture vapor to pass. As a result, the concrete that the coating is attached to will deteriorate and then it peels up.

Thank you! Could I do the Waterproofer and then the TruLock tiles over it once it dries?

Yes, you can do that.

Shea, I did the test this week. I bought the kit on Amazon and followed the instructions. Today, after 72 hours, I got back the dish. I knew it was not good because half of the dish was water. I still weighed the dish, with the tape, and did the calculation the manufacturer’s website. I couldn’t believe my eyes. It was 21.74 pounds per 1,000 sqft in 24 hours. I put the test dish near the outside wall and outside of the garage, the level of the lawn soil is about the same as my garage floor. I live in Florida and it rains almost everyday in recent weeks. I think the water comes from the rain and from the soil to the slab. I also think if I had put the test kit in the middle of the garage, it would have been better. I already ordered ArmorPoxy products with an ArmorUltra Primer https://armorpoxy.com/products/armorultra-primer-2-gal-kit/. Can I still go ahead with my project?

Wow… that is a crazy amount of moisture. Florida is unique in that much of the land is flat and the soil porous. Moisture is rarely forced to the surface from hydrostatic pressure due to a slab being below grade. The moisture is created from the concrete acting like a sponge and drawing it in from below depending on temperature and humidity. You still may be OK. Legacy Industrial, one of our sponsors, deal with this all the time and states it usually is not a problem. However, I would recommend contacting ArmorPoxy to discuss your issue before you precede since you are using their product.

Thank you, Shea. I contacted them and they suggested me to use the Moisture Barrier which can handle this situation but is about 4 times more expensive than normal primer. : (

Yes, moisture vapor blocking epoxy primer is more expensive for sure. If your slab was below grade, we would definitely recommend it. Because your slab is on grade, you may not have an issue with the standard primer since the water is not being forced up under pressure, but it’s still a gamble.

We had our garage floor coated with epoxy like many of our neighbors here in Annapolis MD, but soon afterwards a brown, oily substance began coming up through the floor. The contractor said our floor probably has moisture coming up & suggested we drill holes in the coating to let it escape. This accomplished nothing. We consulted another contractor who suggested removing the coating and performing a moisture test. We did that and he said he’s never seen test results as high as ours – 22 lbs/1000 sq ft/24 hrs. He said he cannot apply a coating on our floor & suggested we seal it with a breathable coating which we are unable to find due to such high test results. We question whether the test was done in proper environment or if that matters. Our garage was 80-110 F & very humid when the test was conducted over 3 days. Does that matter? If the test results are accurate, can we simply install breathable mats over it w/o sealing it? Thanks for any help!

Hi Tim. Yep, the oily substance is the byproduct of moisture in the concrete mixing with minerals and other ingredients in the concrete. Is your slab below grade or up against a hill or bank? If so, that could explain your moisture issue. Water that does not drain away from the slab or pools against the foundation can cause moisture issues as well. Generally, humidity will not affect the test results. However, if the dome of the test kit was not sealed properly to the concrete it can skew the results. In addition, if water had been introduced to the surface within the previous 48-72 hours, it may not have had time to completely dry throughout the slab and the heat would cause the moisture vapor from within to rise and produce high readings. If any of those two were the case, you may want to test again to see if you get numbers low enough that will qualify for a moisture blocking epoxy primer.

Garage floor mats are made of polyvinyl and are not breathable. They will block moisture transmission and get wet underneath. If you want a breathable option, we would highly recommend polypropylene (hard plastic) interlocking garage floor tiles. They are breathable and allow for air circulation under the tiles. You can learn more about them here.

Hello, I am looking for some advice, our rumpus room in our single story home has moisture coming up through the concrete slab, a reading of 17%.

We want to install engineered timber flooring on the slab however we are concerned about the high moisture

that will most likely cause mold under the timber flooring without any coating on the slab.

We have had a company advise they can apply 3 coats of hydrostatic pressure resistant epoxy coating flooring on top of the concrete slab to stop the moisture coming up.

I am concerned this may damage the slab over time and also concerned humidity will be trapped inside the room and still may cause mold under the timber flooring above the epoxy flooring.

What are your thoughts?

Hello Ben. Is your slab below grade or up against a hill? The 17% RH reading does not provide enough information for us since we don’t know exactly what type of RH test was performed. Most require drilling a hole in the concrete in various places to place meters. What we can tell you, however, is that moisture vapor blocking epoxy primer coatings do just what they say – block moisture vapor transmission. It will not cause damage to the concrete. This is a common practice in the coating and flooring industry providing that the moisture vapor readings are not too high. We are assuming that the company who recommended this process has already verified that the moisture vapor content does not exceed the parameter of the coating. I’m not sure why you believe that humidity will be trapped inside the room when moisture vapor is being blocked. Can you elaborate?

Hello,

The slab is not below grade, we are at the bottom of a hill, there is a retaining wall about 1.5 metres away from the house.

They tested the moisture with a surface probe, no drilling. I am not sure of what the 17% measurement is myself.

The room with the higher than average floor moisture reading seems to be very humid, it has bad ventilation and we live in a tropical climate area. I am just worried with bad ventilation, them installing vapour blocking epoxy on the floor, this might cause humidity build up between the epoxy and engineered timber flooring that will go over the top of the expoxy. My big concern is mold forming.

Hi Ben. OK, we can see why you may have moisture in that room. Also, make sure that water easily and quickly drains away from the area between the house and retaining wall or the slab will soak it up like a sponge. It sounds like the contractor used a pinless moisture meter. The 17% does not help us unless we know in what measurement reference it is related to. However, if it was determined that the readings were sufficient for a moisture blocking epoxy, then the humidity in the room will decrease quite a bit as a result. This is assuming the main source is from the floor and no where else. Humidity in the room cannot build up if moisture is being blocked from entering.