This post may contain affiliate links. If you use these links to make a purchase, we may earn a small commission. As an Amazon Associate, All Garage Floors earns from qualifying purchases. You can read our full disclaimer here.

By far, the biggest complaint that people hear about epoxy is that it peels up off the garage floor soon after application or within a year of it being installed. What many who are interested in epoxy garage flooring do not realize is that well over 99% of all these complaints do not involve a defective epoxy product. If that’s the case, then what causes epoxy coated garage floors to peel up in the first place?

What’s interesting to note is that the majority of complaints about epoxy garage floors are from DIY applications. There is a valid reason for this. The average DIY installer usually isn’t that knowledgeable about how to apply garage floor epoxy to begin with. When you couple that with the fact that many of the inexpensive epoxy floor kits make application sound as easy as rolling paint on a floor; you now have the potential for failure.

I followed the instructions exactly and it still peeled up

Many of these complaints start with the statement, “I followed the instructions exactly and it still peeled up”. The sad part about this is that many did follow the instructions exactly as stated, but that does not mean that what they did actually prepped the concrete properly.

We will explain shortly.

The main culprit to garage floor epoxy peeling up is poor preparation of the concrete surface. This can be attributed to a variety of factors.

Epoxy needs a clean and porous surface in order to achieve a mechanical bond to the concrete. If you don’t have that, it’s almost guaranteed that your coating is going to fail at some point.

As an example, lesser expensive epoxy kits generally come with safe to use, biodegradable solutions that are supposed to clean and etch the concrete simultaneously in order to provide the proper surface profile for epoxy. In many cases however, these do not work well.

But how is the average DIY installer to know?

If you don’t know what the surface should look like when the concrete prep work is done, how it should feel, and how to test it, then it really is a gamble whether or not your epoxy coating is going to peel or not.

Why epoxy floors peel

Epoxy is a very tenacious and tough coating to remove when applied properly. That is why there are so many successful, long lasting epoxy garage floor coatings that people absolutely love. Just about every problem you may have heard about epoxy flooring can be avoided by paying attention to the details. With that in mind, we have listed the seven most common reasons for epoxy peeling up along with the solutions on how to avoid them.

1. Poor surface profile

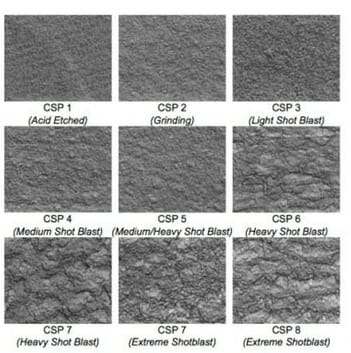

As we stated earlier, a poorly prepared concrete surface is the main culprit to epoxy peeling. The number one problem associated with that is a bad surface profile. Surface profile is the roughness and porosity of the concrete that allows for the mechanical bond of the epoxy.

These are examples of concrete surface profiles. Most epoxy requires at least a CSP 1 or CSP 2 profile to achieve the proper mechanical bond.

In order to obtain the correct surface profile for epoxy, you need to acid etch the concrete at the very minimum. Grinding the concrete is the preferred method, but it’s not always feasible for the average DIY install. You can read more about acid etching versus grinding here.

Profiling the concrete exposes the pores so that the epoxy can sink in a little to get the bite it needs to adhere as well as it does. If not done correctly, the epoxy will not adhere well and can start to peel at some point after application.

Once the concrete is profiled correctly, it should have a lighter appearance and a rougher texture to it that is similar to 100 grit sandpaper. Test it by dripping some water onto the concrete in various areas. The surface should immediately turn dark and absorb the water in less than a minute.

Beware of the clean and etch solutions that come with the lesser expensive, single coat garage floor epoxy kits. Many times these solutions are not effective enough to create the proper surface profile.

The reason for this is that these solutions generally consist of citric acid crystals. The main reason for using citric acid by these manufacturers is that it is safe for the environment and it is much more difficult to harm yourself if used improperly. We have more info here if you are concerned about etching with safer alternatives.

The problem however is that citric acid is the weakest of the concrete acid etching solutions and it will not profile a hard troweled or machine troweled surface effectively. It does not work well on extremely dense concrete either.

Another problem with these citric acid products is that they are touted as a cleaning solution as well. If these solutions are applied to a dirty concrete surface, they do not work well at cleaning and etching the concrete at the same time.

When acid etching a garage floor, the concrete should always be cleaned thoroughly first before applying the acid etch.

Muriatic acid or phosphoric acid is the preferred acid to use for achieving the proper surface profile for an epoxy coating. You can read more about how to acid etch properly here.

2. Moisture

The second most common problem associated with the peeling of epoxy garage floors is moisture in the concrete.

Water vapor cannot pass through epoxy. If you have moisture under any part of your slab that is below grade, the hydrostatic pressure that is created from water vapor being trapped under the epoxy coating can create enough force to lift the epoxy right off the surface.

Inspect your floor for signs of moisture. Efflorescence is the very first sign that you may have a moisture problem. So are dark spots on the floor.

If your slab is below grade on any side then it’s imperative that you do a simple moisture test first before starting an epoxy floor project. You can learn more about moisture in concrete and how to test for it here.

3. Oil and contaminants

Once you have achieved the correct surface profile for epoxy, it’s important to check that any oil stained areas that were previously cleaned are absorbent and not repelling water. These are areas that you will want to check with the water drop test.

It’s not uncommon for a previously oil stained area to be darker in color than the surrounding concrete. As long as it absorbs water, then it will absorb epoxy and provide for good adhesion.

Other contaminants such as silicone from tire dressing products and polymer compounds that leach out of warm tires will not allow epoxy to adhere either. Be sure to perform a water drop test around the areas where the car tires sit as well.

Acid etching will not remove silicones and tire polymer residue. If you acid etched the concrete and these areas do not pass the water drop test, you will need to grind the concrete to remove the residue.

4. Acid etch residue on the surface

When you acid etch your garage floor the acid solution works by reacting with the free lime in the concrete. This causes a breakdown of the calcium at the surface which exposes the open pores of the concrete. This calcium is then deposited onto the surface in the form of a very fine white dust.

Many epoxy floors have peeled up because this fine white dust was not effectively removed before the epoxy was applied.

Because the dust is so fine, it likes to stick to the irregularities in the surface and can be difficult to remove. If epoxy is applied over concrete with this fine white dust, the epoxy sticks more to the dust and not the surface. It will eventually peel up exposing the white dust on the underside of the peeled epoxy coating.

The amount of dust left on the surface after acid etching is dependent on how much free lime was present in the surface of the concrete to begin with and how well the floor was neutralized and flushed afterwards.

Never let the floor start to dry during the acid etching process and use liberal amounts of water when flushing the surface. It helps to use a deck brush to lightly scrub the surface as it is being flushed. If you end up with this white residue it can be removed, but it may take multiple scrub downs to get it all off the surface.

A pressure washer works best. If you don’t have one available, wet the floor down in sections and use a solution of TSP and hot water to scrub the surface. Flush it well with a high pressure nozzle and move on to the next section. It will come off, but it may take a few tries.

5. Sealed concrete

Epoxy will not adhere to concrete that has been previously sealed and acid etching will not remove a sealer. As we have stated previously, acid only responds to the free lime in concrete. If the concrete is sealed, the acid etch solution will just sit on the surface and not do anything. More than one case of epoxy peeling has been from people attempting to acid etch a sealed garage floor.

The only way to profile a previously sealed garage floor correctly is to grind it. Grinding the floor will remove the sealer at the surface and profile it at the same time.

If you are not sure if your floor has a sealer, then you need to do a concrete sealer test. Do this by dripping water over various areas of the concrete. If the water immediately beads up or if it just sits there for a few minutes without being absorbed into the concrete, then you have a sealer on the garage floor.

If the concrete turns dark and the water is absorbed after a few minutes, then you don’t have a sealer on the floor.

If your tests are inconclusive, apply a few drops of diluted muriatic acid to the surface. If it starts to bubble and fizz, then no sealer is present. If it just sits there like a drop of water and does nothing, then the concrete is sealed.

6. Excess laitance

Laitance is a weaker top layer of cement. Sometimes it can have a crazed look to it with what appears to be very fine cracks. It consists of a fine cement paste top layer that is produced by excess bleed water when troweling the finish. It can also be caused by concrete finishers who spray water on the surface of the concrete to make it smoother.

Grinding the concrete will remove this fine layer and prep the surface properly for epoxy. Acid etching on the other hand will not do this very well. It will only rough it up. What you end up with is a softer concrete surface that is not bonded well to the rest of the concrete.

When epoxy is applied to this type of surface, it creates a weak mechanical bond to the concrete that can eventually cause it to peel up at a later date. Concrete dusting is a sign of excess laitance and sure indication that you should grind the garage floor instead.

If you don’t have dusting, test the concrete for excess laitance by scraping the surface hard with the tip of a screw driver. It shouldn’t leave much of a mark if any at all. If it doesn’t, then you should be OK to acid etch.

7. Soft concrete surface

A soft concrete surface can be caused from poor concrete, bad finishing or a combination of both. Indications of soft concrete include heavy surface dusting, areas that are easily scarred or gouged, and crumbling concrete.

The only solution to a soft concrete surface is to grind it. It may also require application of a densifier to harden the surface. Sometimes even that will not prepare the concrete properly for epoxy.

This video is a great example of a floor that needed extensive repair before the epoxy was applied. Epoxy coatings will not fix a bad concrete surface.

If you have a soft concrete surface, we recommend contacting a professional floor coating company or installer to inspect the surface and do the job for you if they deem it feasible. If you are looking for a DIY garage flooring installation, then interlocking tiles or garage floor mats may be a better solution for you.

Final tips

One thing to remember is that the lesser expensive garage floor epoxy kits will eventually wear out in high traffic areas. This is not the same as peeling. You will notice that the floor in these areas will become dull and the concrete will start to show through. This is a result of abrasion at the surface of the coating and not from peeling.

Hot tire pickup is not necessarily a sign of bad floor prep either. Again, the lesser expensive epoxy products can be prone to this no matter how well the floor was prepared. The reason is due to the low solids content of the epoxy as well as the chemical makeup.

Applying a successful epoxy garage floor coating that does not peel truly is not that difficult. It just requires some attention to detail and knowledge of how your garage floor concrete should be prepared and tested before application.

With the exception of moisture issues, most of these common problems with epoxy peeling can easily be avoided just by grinding the garage floor.

However, whether grinding your floor or acid etching, if you pay close attention and follow these tips you should have a successful epoxy coating that will not peel after application.

On the best epoxy for a typical garage floor- sorry , my bad

OK, that helps. There is not a typical best epoxy brand to use. If you are looking for quality and want something to last, then you need to avoid the typical DIY floor coating kits that you can purchase from your local home improvement center. Here is an example. A quality epoxy coating is put together as a system. We discuss that here including defining better type of products. Lastly, one of the top performing systems that is the easiest to install is single-part polyurea. We discuss that here.

Tremendous!

Good job by you!

What to do if your floor has peeled?

How do you get rid of the existing paint?

Hi Karen. The best thing to do is grind the floor to remove any old paint or coating. This properly prepare the surface for a new coating as well.

Hi should i grind the concrete right down to the aggregate? I can see aggregate in some areas but not all. Is it true we should remove the cream coat completely off the top?thanks

Hi Tim. No, you do not want to grind down to the aggregate if you can help it. The only reason to do that is if you have a slab with an extreme dusting problem and you need to remove the upper soft layer.

This is a little different question, but how soon could you put a treadmill down on the floor without messing it up? Thanks!

You typically want to wait 24 hours before walking on it, 48 hours before moving things in, and 3-4 days before parking a car.

Thank you!

Can I buy the high quality epoxy that will resist hot tire pick-up at my local hardware chain?

Hi Julian. No, hardware chains and home improvement centers only carry the residential quality DIY kits such as Rust-Oleum, EpoxyShield, H&C Shield-Crete, and etc. These are all low solids epoxy kits that do not perform well when it comes to hot tire pickup or longevity. They are created and priced to attract the DIY crowd who are not very educated in terms of coatings. I suggest reading our article here that explains in detail what to expect with coatings and the differences between these lower-cost kits and commercial quality kits. Most high-quality epoxy is sold by vendors online that specialize in concrete coatings. We have a list of our recommended sponsors that sell high-quality epoxy in this article here. They are not the only vendors, but it’s a good representation of those that do.

Hi, recently purchased over $1,000 of Rust-Oleum 3.78L Gunmetal Metallic Concrete And Garage Floor Paint to paint our double garage and driveway concrete. I prepped and painted as per the directions on the label, waited 6 days before we drove a car on it……….the first day we parked the car on it the paint has ripped up on the driveway????!!!!

Understandably we are not happy and I am now too scared to park anywhere on the driveway in fear it is all going to rip up! Having spent so much money on the product and put so much time into it we are very disappointed

Can you please suggest what we can do to try and patch this area and prevent it happening further??? Is there a coating we can put over the top to stop the hot wheel pickup?

Any help much appreciated. Cheers, Jamie

Hello Jamie. We are sorry to hear about your issues. I wish we had better news for you, but unfortunately, we have heard this same story far too many times. Paint and 1-part epoxy paints are not coatings. They do not adhere as well as coatings to the concrete and they all will peel from car tires at some point. It’s just a matter of when. This article here explains the differences. It doesn’t matter what the marketing on the cans states about resisting hot tire pickup, it’s going to happen with paint. In addition, paint is not designed to have coatings applied. They are not compatible. Lastly, the problem is the paint adhering to the concrete. Placing a coating over it is not going to prevent that from happening. It’s not uncommon for penetrating sealers to be applied to concrete driveways. Did you test for that? If not, it’s something that could be contributing to the problem.

Paints and coatings typically are not a good idea for driveways as well. They can be very slippery when wet. In addition, many coatings and some paints are not U.V. stable and will deteriorate from long-term exposure to direct sunlight. As much as it hurts to say it, your best bet is to remove the paint from the driveway with a 3000 PSI or higher pressure washer. Treat the concrete to a penetrating sealer and leave it at that.